BRAKE FLUID SIGHTCAP

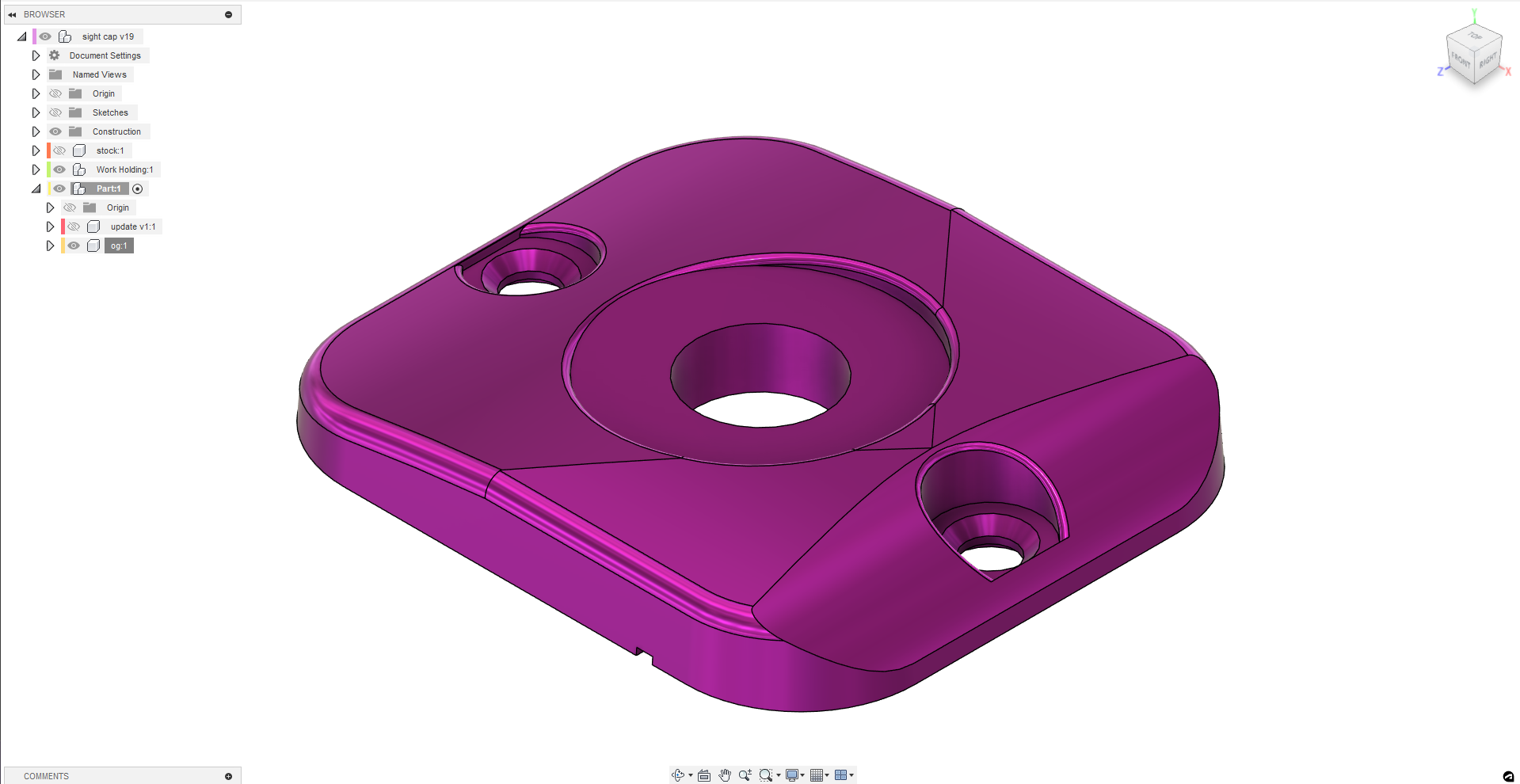

This component is part of a handlebar assembly for my friend's motorcycle.

download1

11

1171

updated 7 hours ago

Description

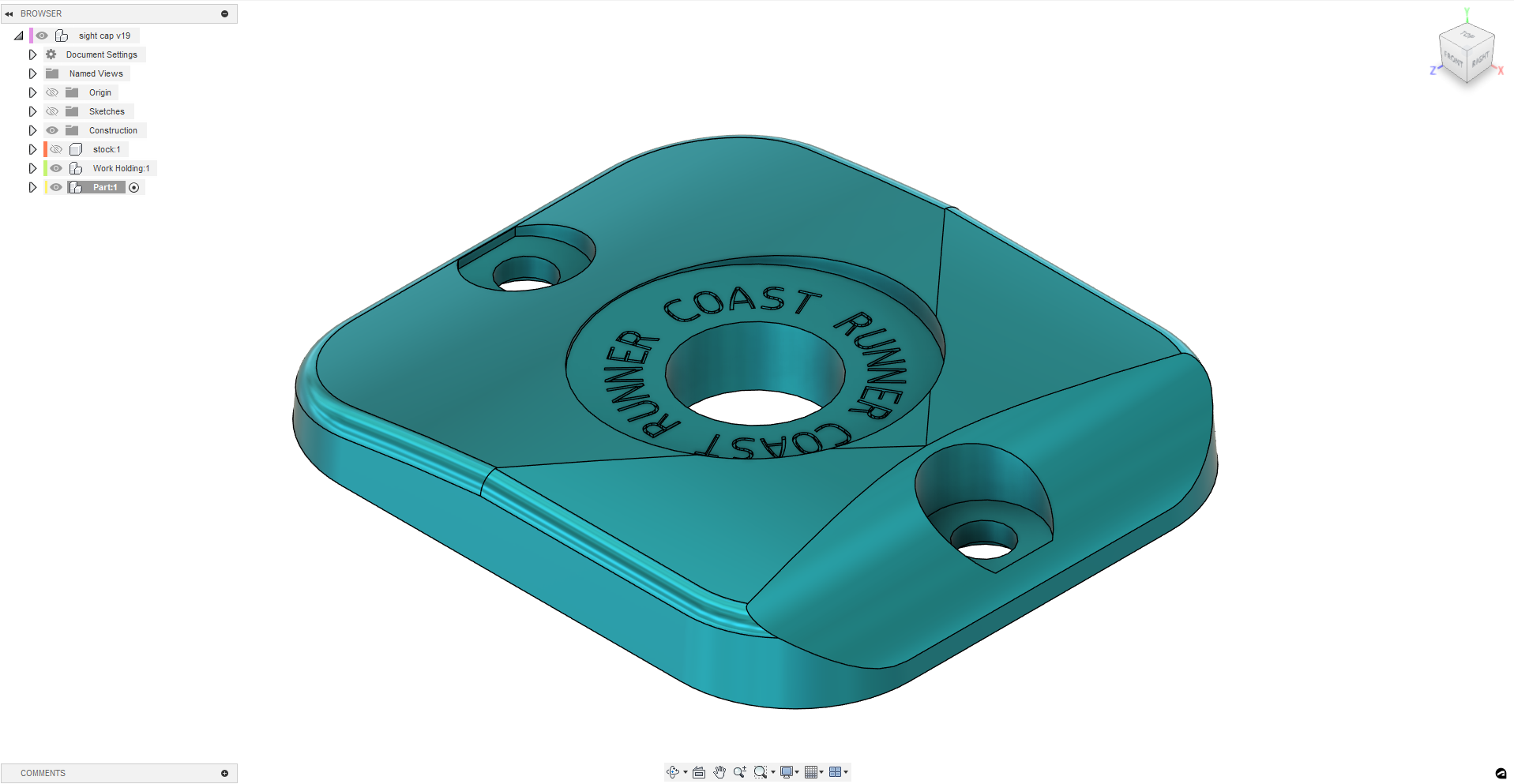

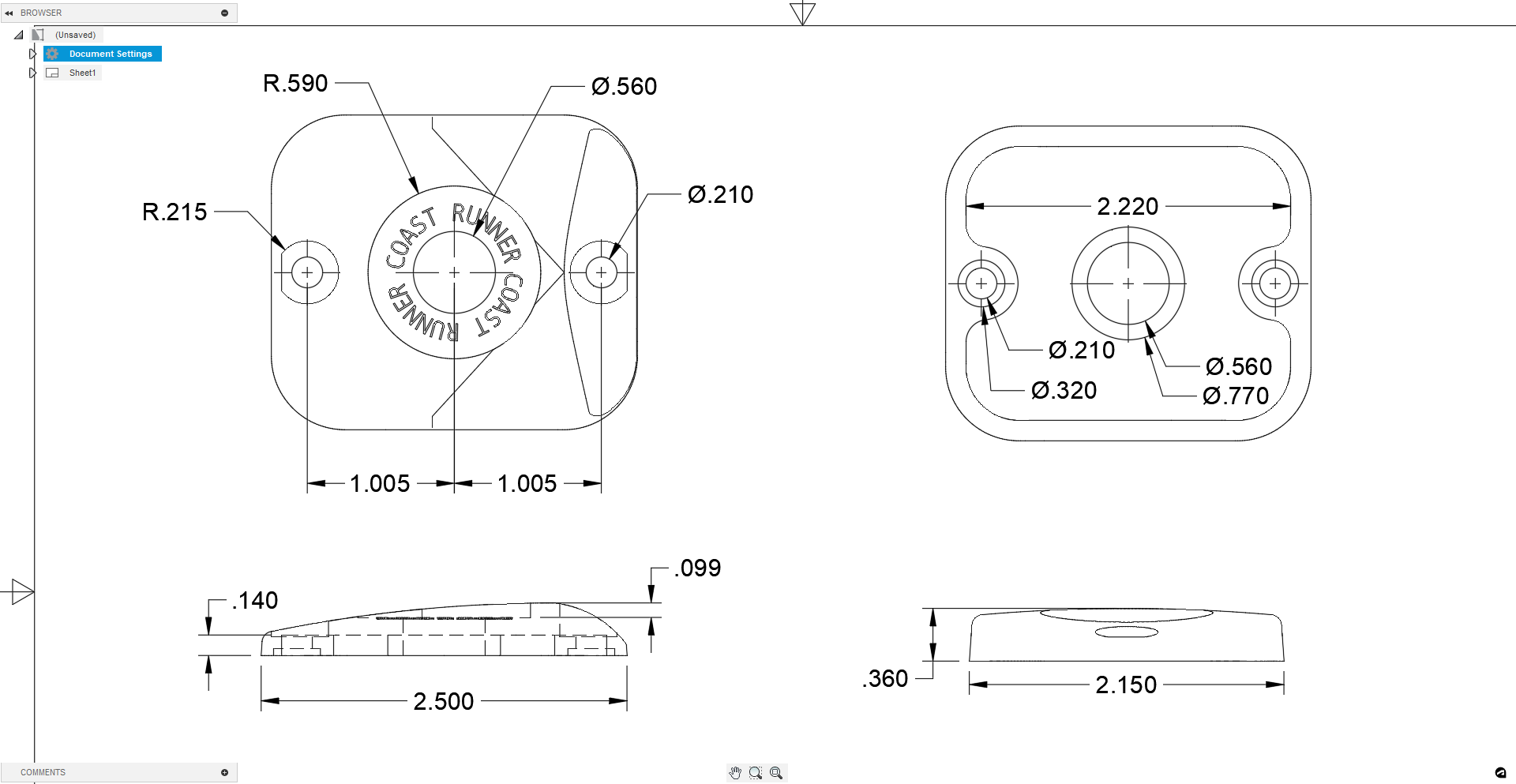

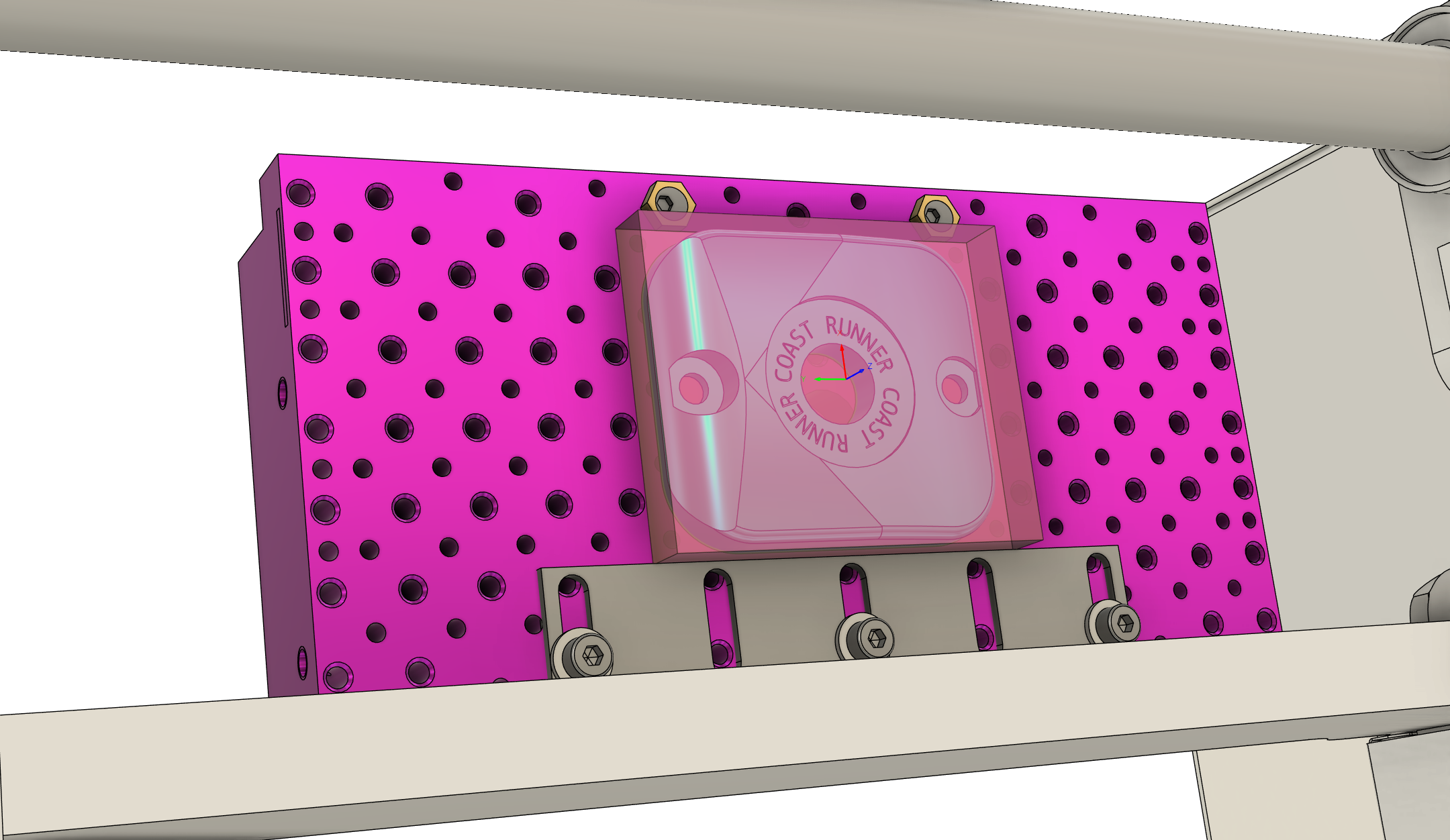

This component is part of a handlebar assembly for my friend's motorcycle. There is a rubber gasket and crystal that insert into the main bore to allow visual inspection of the brakefluid levels at a glance.

The reverse engineered model had to be editted in order to manufacture using the CR-1. This project includes all the setup information and NC Programs necessary to mill this model. Given the simplicity of the project it is unnecessary to make a .crproj and the source file can be used as a starting point for any sight cap within this work envelope.

STOCK:

Aluminum 6061

2.25" x 2.75" x 0.37"

The larger dimensions can be used from normal stock suppliers like McMasterCarr but the 0.37" thickness is the absolute minimum which can be larger by up to 0.01". You can always use the manual mode and basic facing operations to creep up on this dimension.

TOOLS:

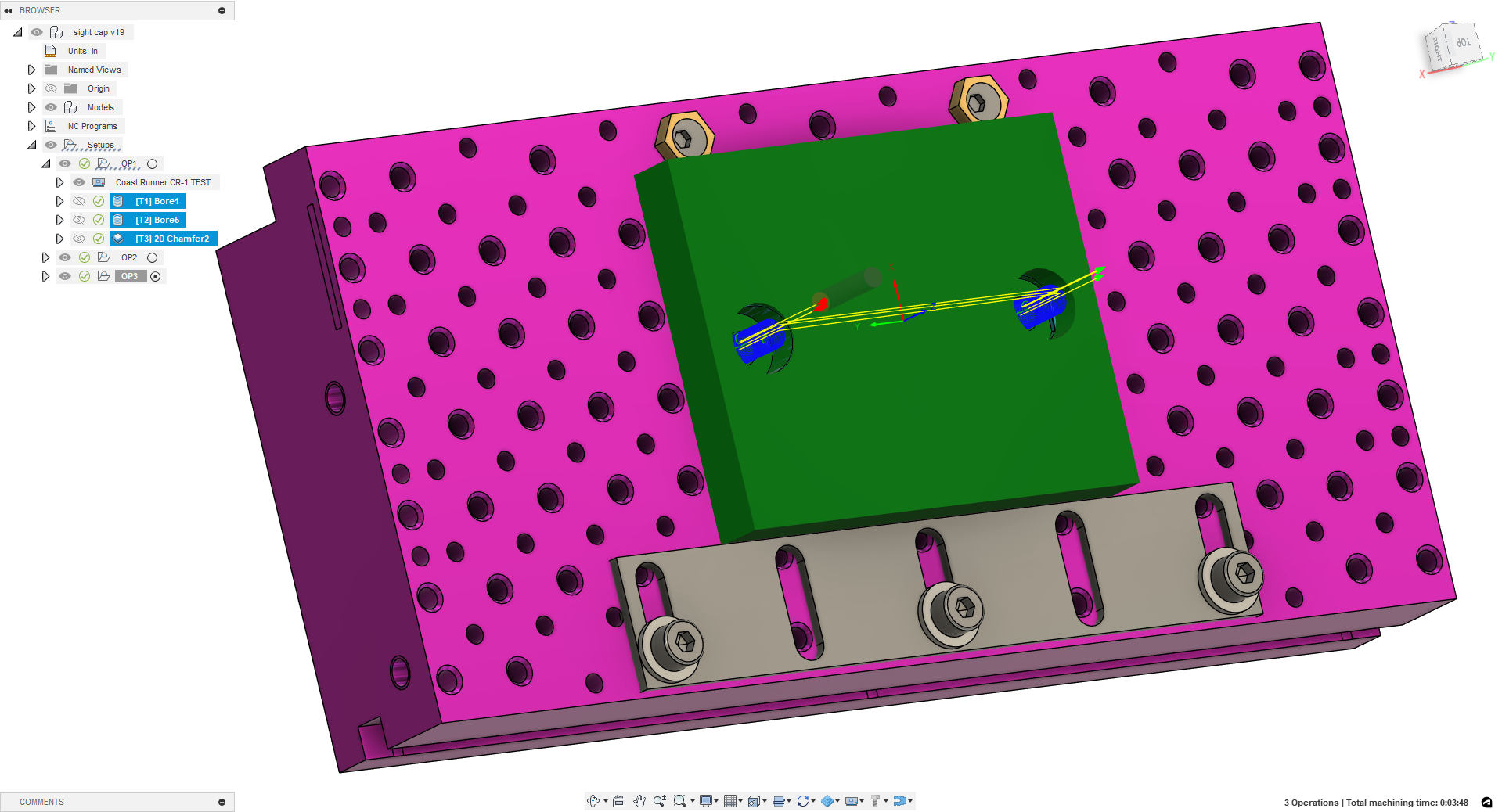

You will need to jog the machine using manual mode in order to replace the tools. Make sure the tool that is installed in the machine is the tool called for with the tool.

T1:

DIA: 1/4"(0.25") OAL: 1.125"

3 Flute, Square - 40 Helix, Variable Pitch, End Mill for Aluminum Alloys & Non-Ferrous Materials

Vendor: Helical

Product: 81994

T2

DIA: 1/8"(0.125") OAL: 0.625"

3 Flute, Square - 45 Helix, Variable Pitch, End Mill for Aluminum Alloys & Non-Ferrous Materials

Vendor: Helical

Product: 03017

T3

DIA: 1/8"(0.125") OAL: 0.62"

Chamfer Mill - 4 Flute - 45 Taper - Flat Tip, Milling

Vendor: Titan USA

Product: TC87804

T4

DIA: 1/8"(0.125") OAL: 0.62"

2 Flute, Ball - 45 Helix, End Mills for Aluminum Alloys & Non-Ferrous Materials

Vendor: Helical

Product: 17032

T5 (engraving only)

DIA:5/32"(.03125") OAL: 1.50"

4 Flute Ball Nose End Mill

Vendor: M.A. Ford

Product: 14003120

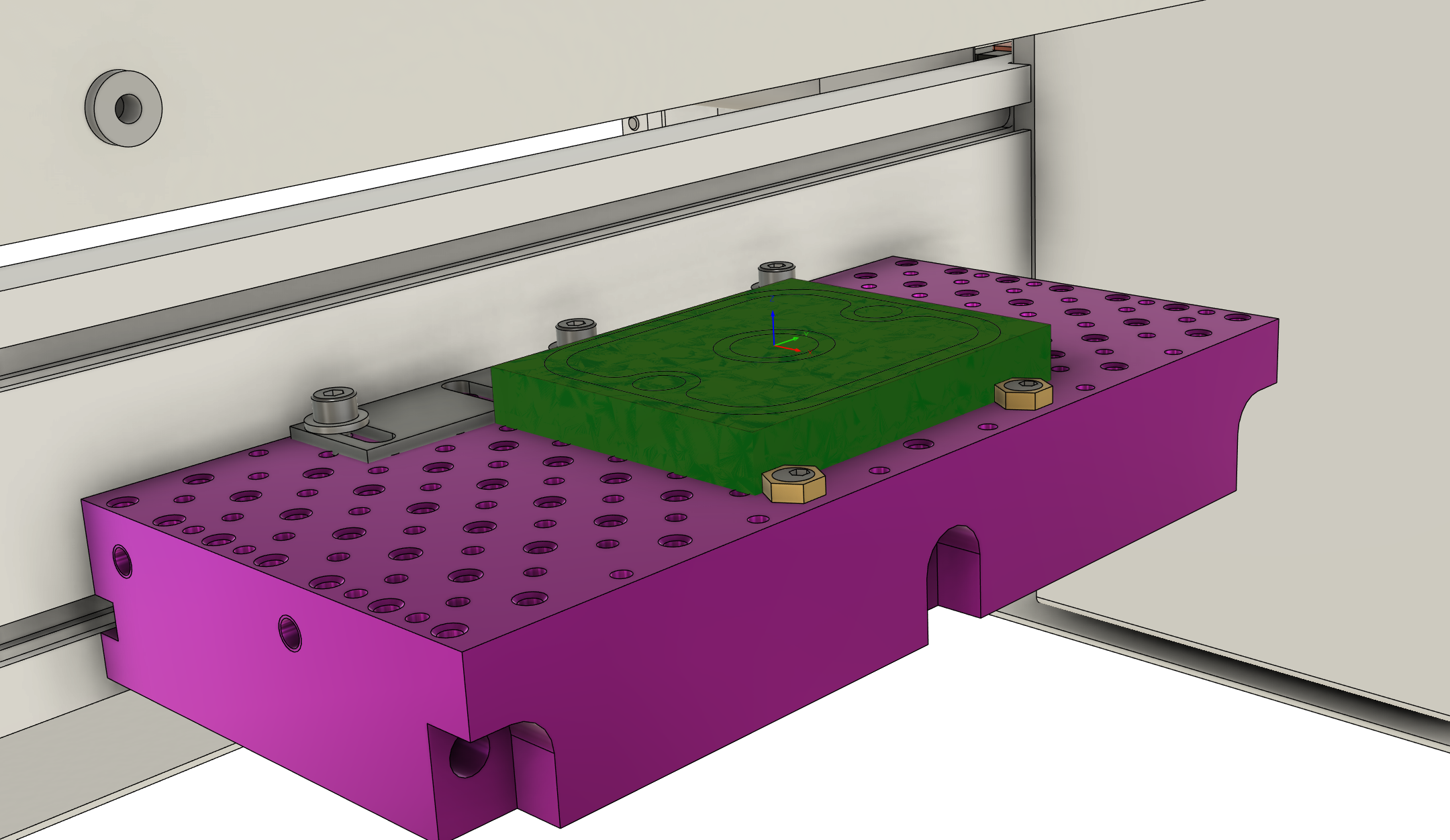

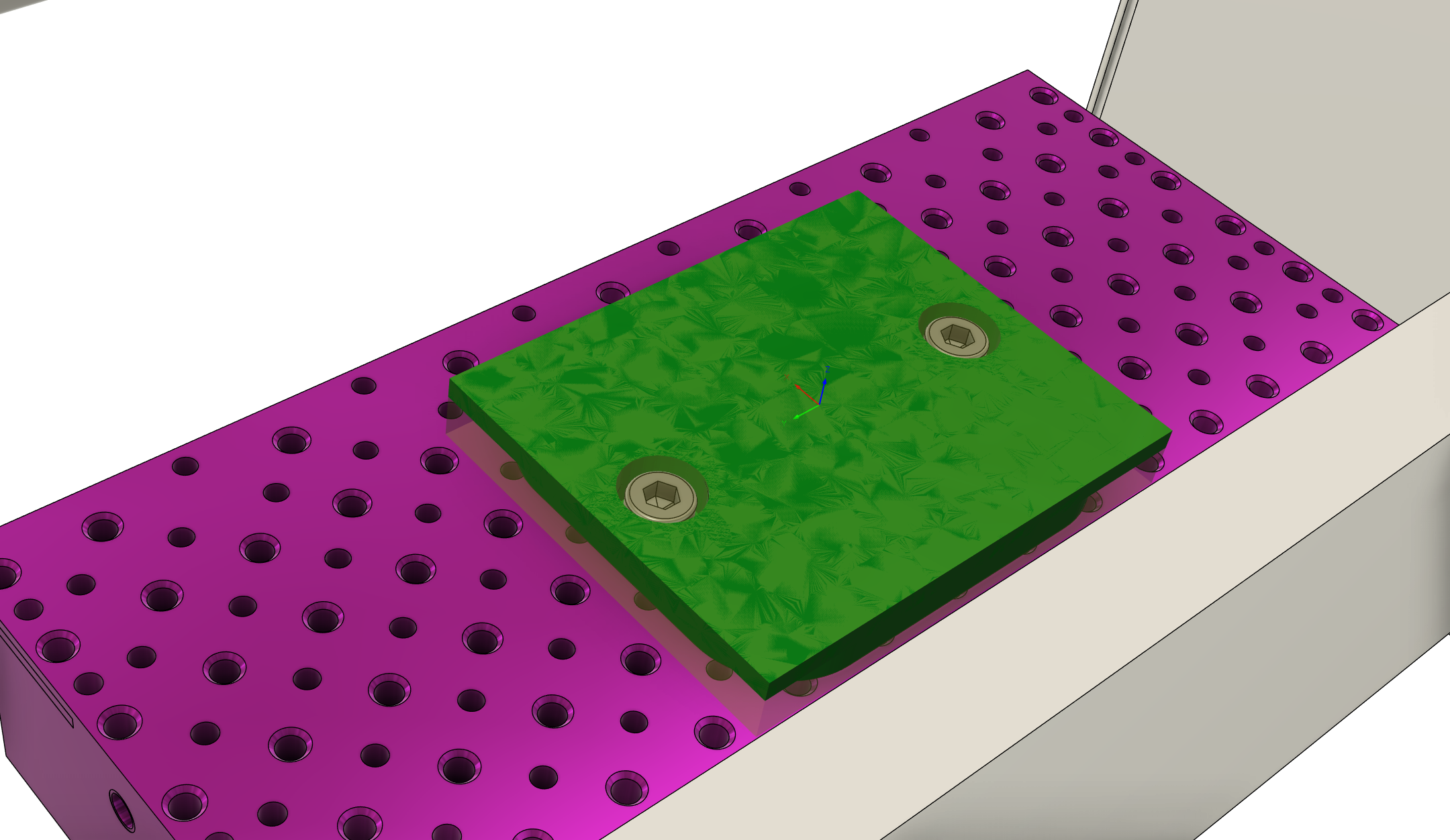

WORKHOLDING:

1x T-Slot Jig Plate (M4 pattern) (with all subcomponents for normal operation)

1x Steel Fence for T-Slot Jig Plate

2x M4 Mitee Bite Fixture Clamps (50204)

2x M4x0.7 x 8 Caphead Screws

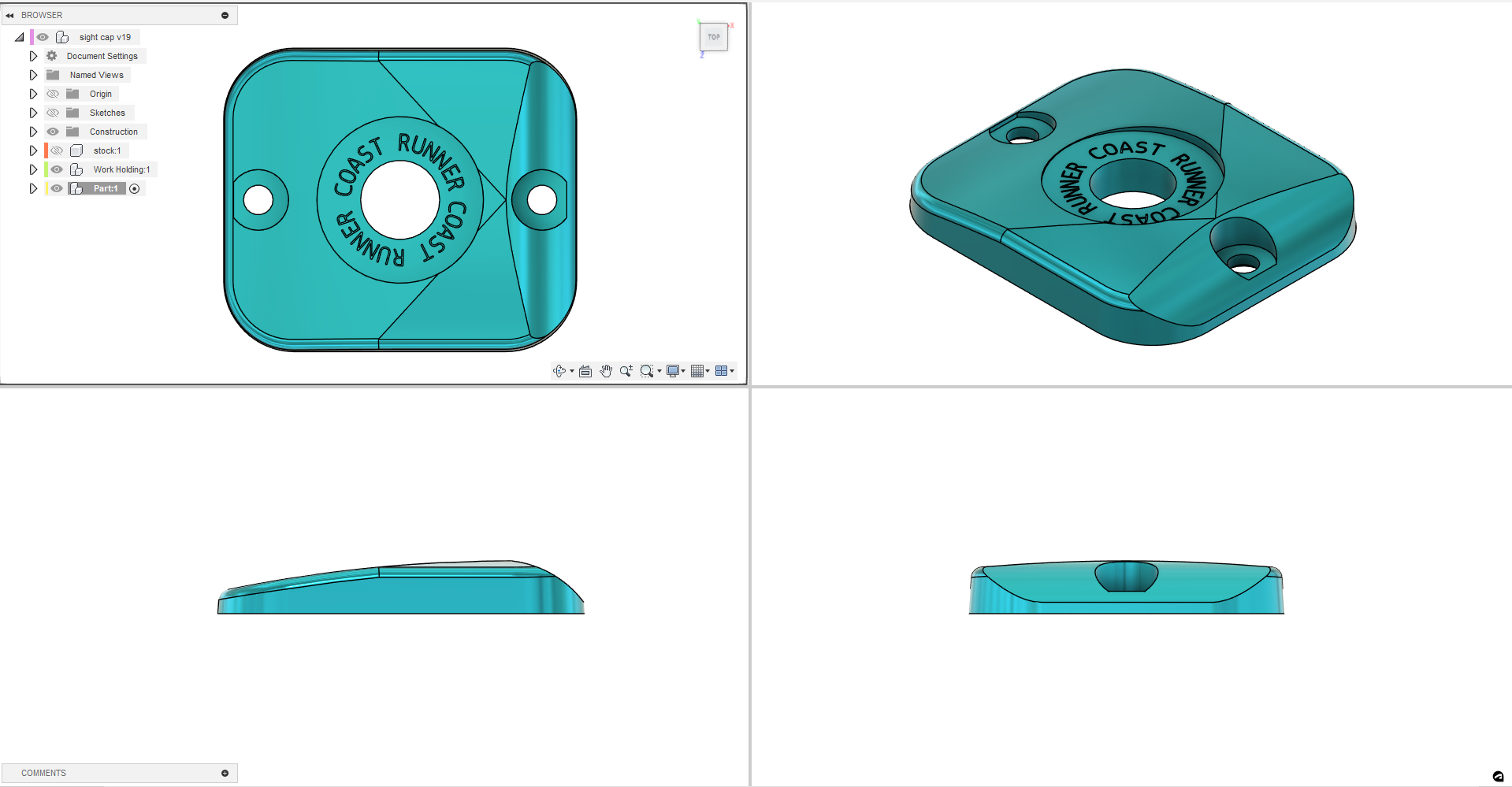

WORK COORDINATE SYSTEM:

The WCS is on G55 for all operations. X/Y are the center of the stock/part and the Z changes per setup but is always the highest point of the stock/part from the T-slot plate. You can set this with manual edge finder or the electrical conductivity probing but this needs to be done manually as no code is included to this end.

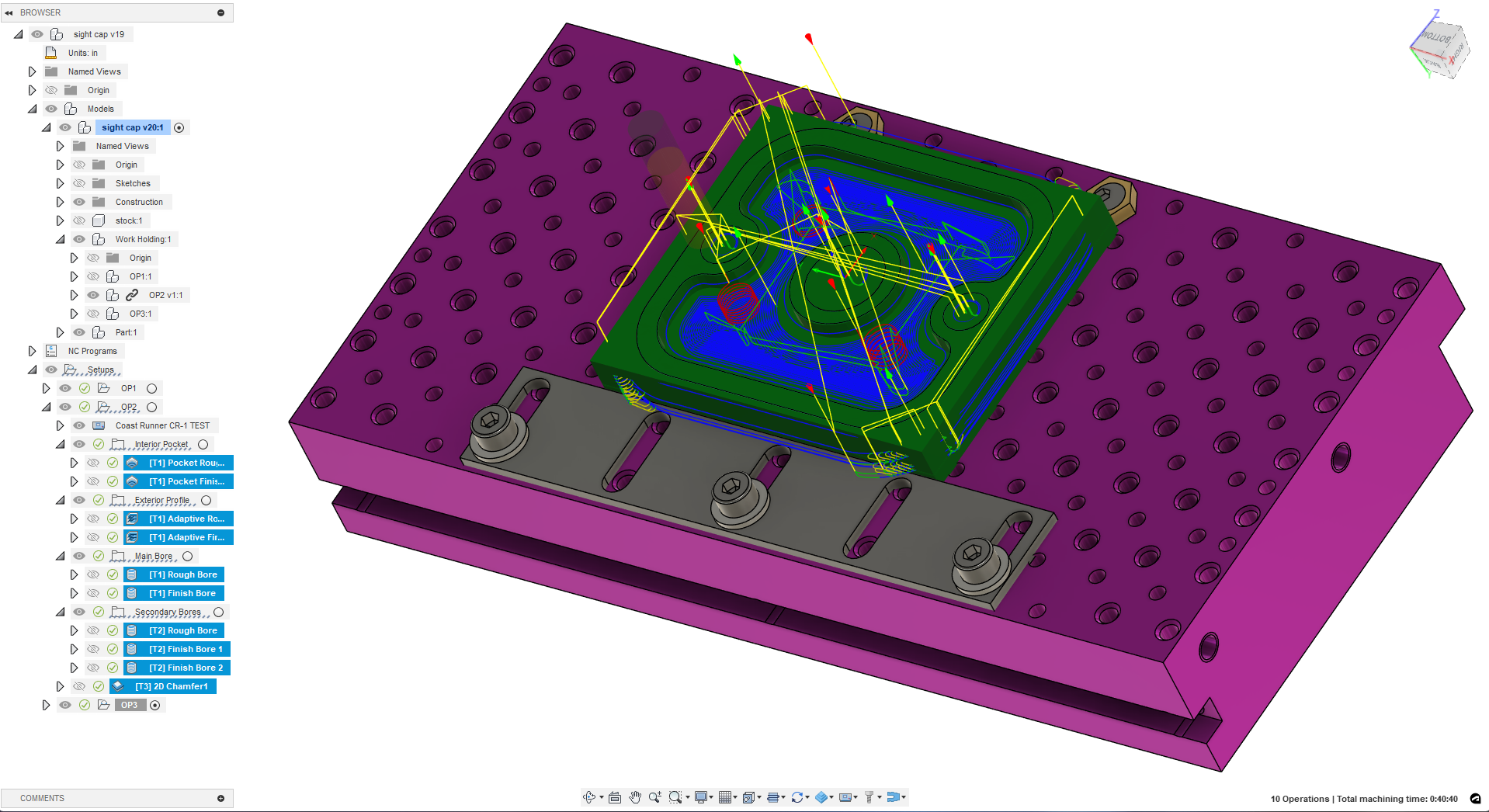

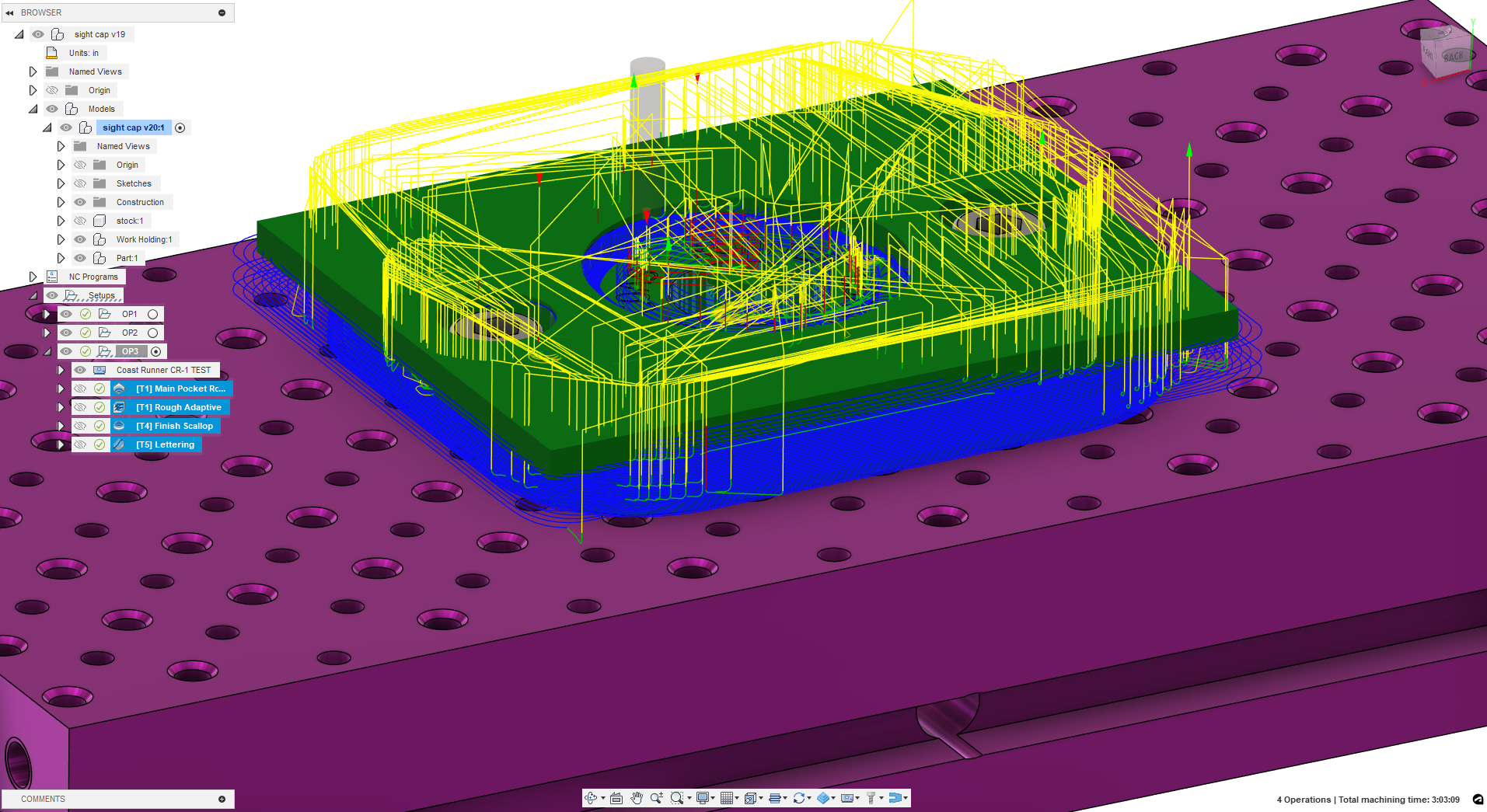

OPERATIONS:

OP1:

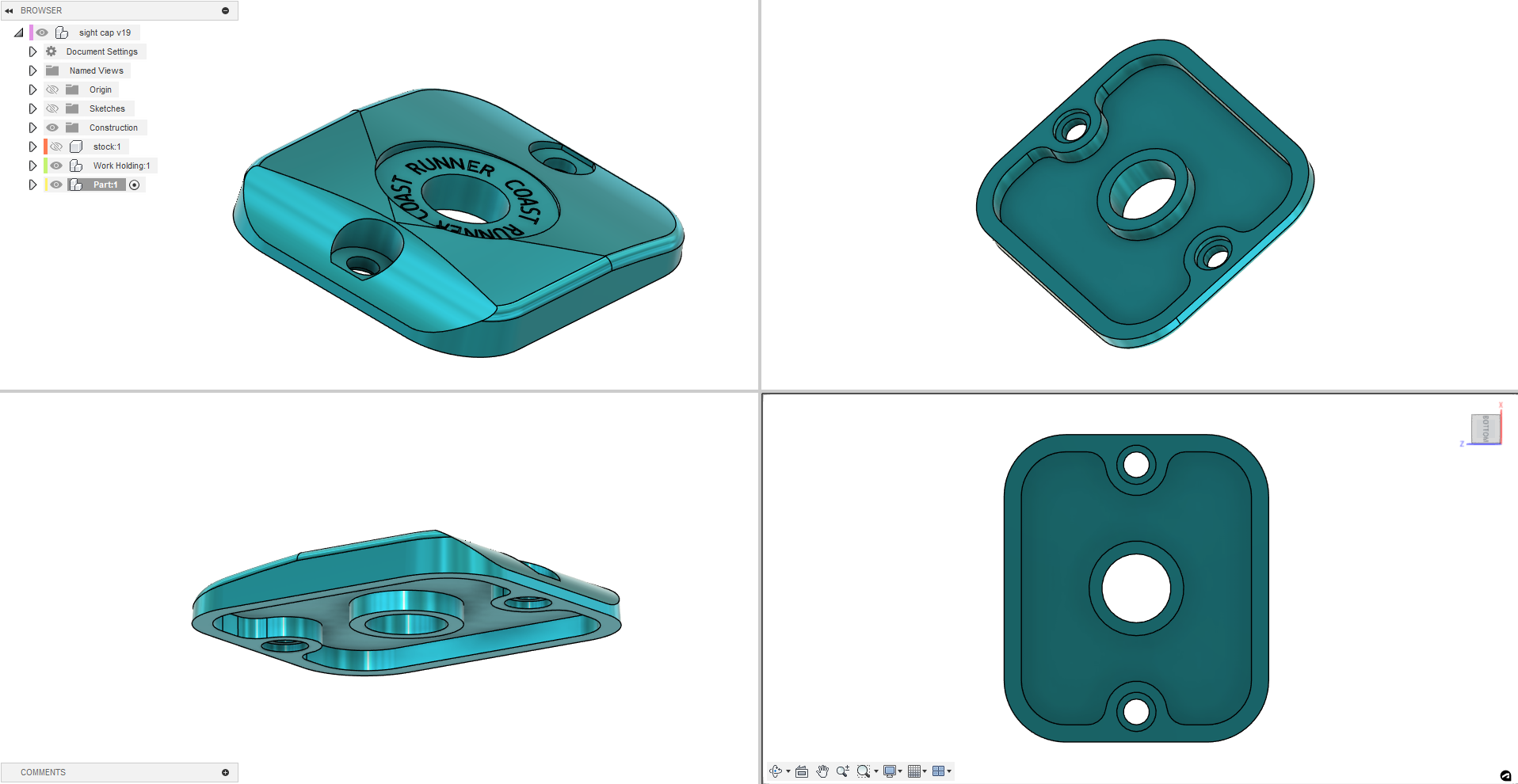

Placing the Fence below and the mitee bites above align the stock so that the 2.75" side is parallel to the table. Set the G55 WCS. This operation is just to create through holes so that the part can be held during OP3. See setupsheet for details.

OP2

Flip the part 180 and re-clamp the mitee bites. Set the G55 WCS(if you use a pin stop then it should be the same as OP1) This operation does all the backside profiling and bores. See setupsheet for details.

OP3

Remove the mitee bites and fence. Use the M4 Bolts and bolt the part directly to the t-slot plate. This operation does the final shape of the part and engraves a logo next to where the sight glass would be shown (optional). The part is now ready for sanding/polishing if desired. See setupsheet for details.

G-CODE NOTES:

All NC Programs are ready for use and indicate setup and necessary tool. The NC Programs are also setup in the .F3Z source file if you want to make edits but I make 2 edits to any given program. The first is that from the first line in the program to WCS indicator (G55) is replaced with:

$H

G0 G90 G94 G17

G20

M3 S4000

G4 P0.5 (spinup delay)

M3 S6000

G4 P0.5 (spinup delay)

M3 S8000

G4 P0.5 (spinup delay)

G90 G94 G17

G55

which homes the machine and gives necessary spinup delay to the tool.The second edit replaces everything between the retract command (G28) and the end of the program with an absolute movement command and a homing operation.

G00 G90 G53 Z-0.02

M30

$H

LISCENCE:

CR-1:Brake Fluid Sight Cap Is Available Under The CC0 1.0 License (Creative Commons Zero).

https://creativecommons.org/publicdomain/zero/1.0/

Material

Tooling

Workholding

Model Origin

The author marked this model as their own original creation.

License ©

This work is licensed under a

Sharing Without Attribution

Remix Culture Allowed

Commercial Use

Free Cultural Works

Meets Open Definition